As a professional in the tech industry, I have been closely following the latest trends and innovations. One technology that has caught my attention is the nema stepper motor, which has revolutionized the manufacturing process.

The Versatility and Precision of NEMA Stepper Motor

NEMA stepper motors are widely recognized for their versatility and precision. These motors provide precise control over movement, making them ideal for applications that require accurate positioning or repetitive tasks. With their ability to move in small increments or steps, they offer unparalleled control over motion.

Furthermore, NEMA stepper motors can operate at various speeds without sacrificing accuracy. This flexibility allows manufacturers to optimize production processes by adjusting speed according to specific requirements.

The Role of Leadshine in Enhancing NEMA Stepper Motors

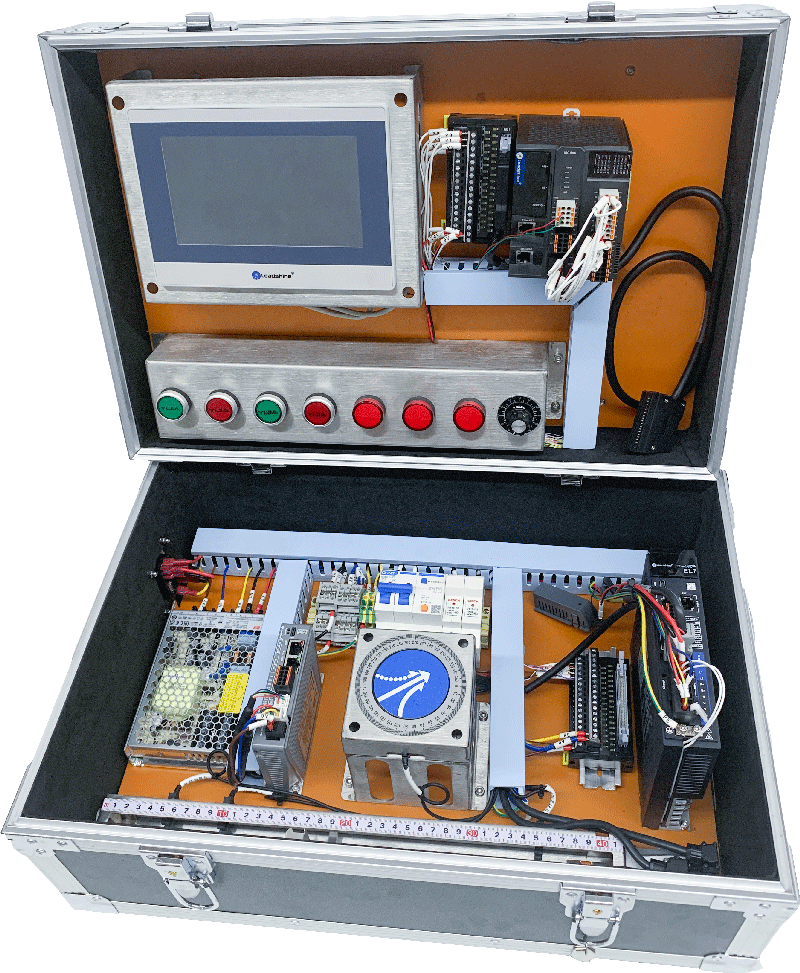

In order to maximize the potential of NEMA stepper motors, it is crucial to choose high-quality drivers like those offered by Leadshine. Leadshine specializes in providing advanced driver solutions that complement the capabilities of these motors.

Leadshine’s drivers ensure smooth operation and precise control over motion while minimizing vibrations and noise. By partnering with Leadshine, manufacturers can achieve optimal performance from their NEMA stepper motor systems.

The Benefits of PLC Remote IO Integration with NEMA Stepper Motors

To further enhance efficiency and productivity in manufacturing processes utilizing NEMA stepper motors, integrating them with plc remote io systems proves highly advantageous.

PLC remote IO enables seamless communication between different components within a manufacturing system. By connecting PLCs (Programmable Logic Controllers) remotely through input/output modules (IO), manufacturers gain centralized control over multiple devices including NEMA stepper motors.

This integration streamlines operations by allowing real-time monitoring, remote diagnostics, and efficient troubleshooting. It also facilitates data collection for analysis and optimization of manufacturing processes.

Conclusion

In conclusion, the NEMA stepper motor has revolutionized the manufacturing process by providing unparalleled versatility, precision, and control over motion. When combined with high-quality drivers like those offered by Leadshine and integrated with PLC remote IO systems, these motors offer even greater benefits in terms of efficiency and productivity.

As technology continues to advance, it is essential for businesses to stay updated on such trends to remain competitive in today’s fast-paced global market.