Are you ready to witness a groundbreaking revolution in the manufacturing industry? Look no further than lsr molding companies. These innovative companies have taken the world by storm with their cutting-edge technology and unparalleled expertise in liquid silicone rubber (LSR) molding.

The Power of LSR Molding Companies

LSR molding companies are at the forefront of transforming ideas into reality. With their state-of-the-art facilities and advanced machinery, they can produce high-quality products with precision and efficiency. Whether it’s medical devices, automotive parts, or consumer goods, these companies excel in delivering top-notch solutions that meet even the most demanding requirements.

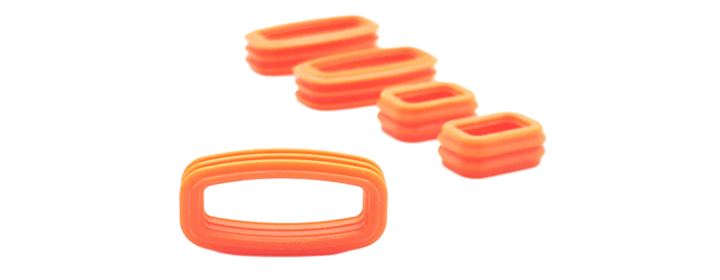

What sets LSR molding apart from traditional methods is its ability to create complex shapes and intricate designs without compromising on durability or functionality. By utilizing liquid silicone rubber as a material, these companies can achieve unmatched flexibility while maintaining excellent resistance to extreme temperatures, chemicals, and UV radiation.

In addition to versatility and resilience, LSR molding offers exceptional biocompatibility properties. This makes it an ideal choice for medical applications such as implants or prosthetics where safety is paramount. Furthermore, its hypoallergenic nature ensures that sensitive individuals won’t experience any adverse reactions when using products manufactured through this process.

JVTECH: A Leading Player in LSR Molding

One prominent player in the field of LSR molding is JVTECH. Renowned for its commitment to excellence and innovation, JVTECH has established itself as a trusted partner for businesses across various industries worldwide.

With years of experience under their belt, JVTECH boasts an impressive track record of successfully bringing countless projects to fruition. Their team of highly skilled engineers works closely with clients throughout every step of the process, from design and prototyping to production and quality control. This collaborative approach ensures that each product meets or exceeds expectations.

What sets JVTECH apart is their unwavering dedication to research and development. They continuously strive to push the boundaries of what’s possible in LSR molding, exploring new techniques, materials, and applications. By staying at the forefront of technological advancements, JVTECH consistently delivers innovative solutions that give their clients a competitive edge.

TPE Overmolding Bonding and Substrate Considerations

In addition to LSR molding expertise, many companies also offer TPE overmolding services. This process involves bonding thermoplastic elastomers (TPE) onto substrates such as metal or plastic components.

When considering TPE overmolding bonding options, several factors come into play. The choice of substrate material plays a crucial role in achieving optimal adhesion between the TPE layer and the base component. Surface preparation techniques like cleaning or priming may be necessary to ensure a strong bond.

Furthermore, understanding the compatibility between different materials is essential for successful overmolding. Companies specializing in this area possess extensive knowledge about various combinations of TPEs and substrates, enabling them to recommend the most suitable options for specific applications.

The Future with LSR Molding Companies

The future looks incredibly promising with LSR molding companies leading the way towards innovation and advancement in manufacturing processes. As technology continues to evolve rapidly, these companies will undoubtedly continue pushing boundaries by introducing groundbreaking solutions that revolutionize industries across the globe.

Click tpe overmolding bonding and substrate considerations.

So buckle up because we’re about to witness an era where imagination knows no limits – thanks to LSR molding companies!